When you hear that something is silver plated, it simply means the item has a thin, beautiful layer of real silver covering a different, more affordable metal underneath—often something like copper, brass, or nickel. Think of it as a gleaming silver jacket worn over a sturdy, less expensive frame. This clever process gives you the look and feel of solid silver without the hefty price tag.

Understanding What Silver Plated Really Means

Silver plating is the perfect marriage of luxury and practicality. It brings the classic elegance of silver to a wider range of items we use every day, from jewelry and cutlery to decorative pieces for our homes. The whole idea is to fuse a micro-thin layer of pure silver onto a strong, budget-friendly base metal.

But this isn't as simple as dipping an object into a pot of molten silver. It's actually a sophisticated process called electroplating. The base metal item is placed in a special bath containing silver ions, and a precise electrical current is passed through it, causing the silver to bond chemically to the surface. The result is a seamless, brilliant finish that’s hard to distinguish from the real deal.

More Than Just a Pretty Face

While the stunning appearance is a major draw, silver plating has a ton of practical uses that go far beyond just looking good. In fact, it’s a crucial technique in many industries because of silver’s unique characteristics. For a deeper dive into how it all works, you can read more in our complete expert guide on what silverplate is.

Here’s why it’s so valued:

- Exceptional Conductivity: Silver is the king of electrical conductivity, which makes it indispensable for coating connectors and components in electronics.

- Corrosion Protection: That thin silver layer acts like a shield, protecting the base metal from tarnish, rust, and other forms of corrosion.

- Natural Antimicrobial Power: Silver naturally fights off bacteria, making it a go-to choice for plating medical instruments and tools.

This mix of beauty and utility has created a huge demand. The global market for silver plating services was valued at around USD 1.2 billion and continues to grow, thanks to its heavy use in the electronics, automotive, and jewelry industries.

How a Base Metal Gets Its Silver Coating

Ever wonder how a plain piece of brass or copper gets that brilliant, shimmering silver finish? It’s a fascinating bit of chemistry in action. The most common technique is called electroplating, and it uses electricity to create a powerful, molecular bond between the base metal and a thin layer of silver.

Think of it less like painting and more like fusing one metal to another on an atomic level. It's a permanent change, not just a surface-level coat.

To get a better picture, imagine you're cooking. The brass candlestick you want to plate is your main ingredient. It gets dipped into a special liquid—an electrolyte solution—which is like a marinade packed with dissolved silver ions. Electricity is the heat that makes the magic happen, binding the marinade to the ingredient.

The Electroplating Journey Step by Step

Getting that beautiful, durable silver layer is a precise, step-by-step process. It all starts with intense preparation, because even a speck of dust can ruin the final look. The base metal has to be perfectly clean—no oils, dirt, or tarnish. It's like scrubbing your vegetables before you cook; any leftover dirt will spoil the whole dish.

Once it's spotless, the object is submerged in the silver electrolyte bath. An electrical current is passed through the liquid, which gets the silver ions in the "marinade" excited. These positively charged ions are drawn to the negatively charged surface of the base metal, where they stick for good. Atom by atom, a new layer of silver builds up until it reaches the right thickness.

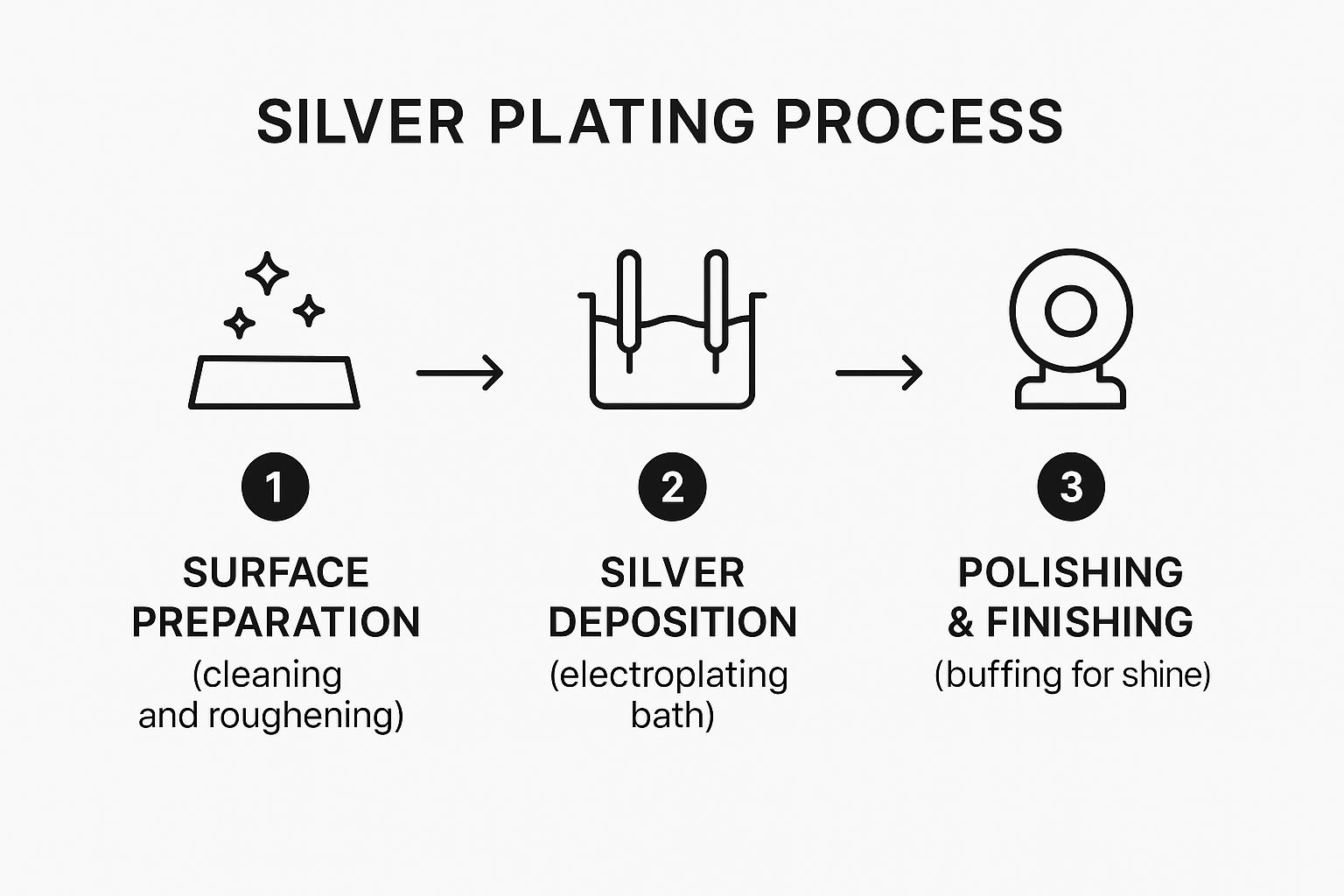

This visual guide breaks down the key stages of the process from start to finish.

As you can see, the journey is meticulously controlled. The prep work is just as crucial as the plating itself, and the final finishing is what gives it that signature brilliance.

Why This Method Creates a Lasting Finish

The real strength of electroplating is that molecular bond. A simple painted-on layer can chip or peel away, but electroplated silver becomes a true part of the object’s surface. This chemical fusion is what gives high-quality silver-plated items their impressive durability and that flawlessly smooth, uniform look.

After the plating is done, the item isn't quite finished. It still needs to be rinsed, dried, and carefully buffed to bring out that mirror-like shine we all recognize. What you're left with is a stunning piece that has the luxurious appearance of solid silver, all thanks to a remarkable scientific process.

Key Takeaway: Electroplating isn't just a coating; it's a chemical bonding process. This is why a well-made silver-plated item can look great for years—the silver is molecularly fused to the base metal, not just sitting on top.

How to Spot Quality Silver Plating

Not all silver plating is created equal. You could have two pieces side-by-side that look identical, but one might be built to last a lifetime while the other starts showing wear in a matter of months. Learning to tell the difference is what separates a savvy buyer from someone who gets stuck with a low-quality piece.

The good news? You don't need a jeweler's loupe or a degree in metallurgy to figure this out. A few key clues—like the thickness of the silver, the metal underneath, and any markings—can tell you everything you need to know about how the item was made and how long its beautiful finish will hold up.

Check the Plating Thickness

When it comes to durability, one thing matters more than anything else: the thickness of that silver layer. This is usually measured in microns, which is just a fancy way of saying one-millionth of a meter. More microns mean more silver, and more silver means a much tougher, longer-lasting finish.

You’ll sometimes see terms like "flash plating," which is code for a super-thin, purely decorative layer, often less than 0.5 microns. It’s pretty, but it’s not meant for anything you’ll handle often. For jewelry, flatware, or anything that gets regular use, you want to see a plating of at least 1 to 2.5 microns. That’s the sweet spot for a good balance of beauty and resilience.

A thicker plate doesn't just last longer—it does a better job protecting the base metal. This is a big part of the answer to the question, does silver plated jewelry tarnish. That silver layer is a shield against the air and moisture that cause corrosion.

Inspect the Base Metal and Finish

What lies beneath the silver is just as important as the silver itself. Quality pieces almost always use a solid, sturdy base metal like brass, copper, or a nickel-silver alloy. These metals give the item a nice, satisfying weight and provide a stable foundation for the plating to adhere to. If a piece feels suspiciously light or flimsy, that’s often a red flag.

Next, it's time for a quick visual inspection. Hold the item up to the light and run your fingers across its surface.

- Look for a smooth, even surface: High-quality plating should have a consistent, almost mirror-like shine with no blemishes.

- Check for flaws: Any little bubbles, pits, or signs of flaking are tell-tale signs of a rushed or sloppy plating job.

- Examine the edges and corners: These high-wear areas are the first place a cheap plating job will start to rub off.

To help you tell the difference at a glance, here’s a quick comparison of what to look for.

High-Quality vs. Low-Quality Silver Plating

| Characteristic | High-Quality Plating | Low-Quality Plating |

|---|---|---|

| Finish & Luster | Smooth, uniform, mirror-like shine. | Uneven, dull, or has visible bubbles, pits, or flaking. |

| Thickness | Generally 1 micron or more, providing durability. | Often "flash plated" at <0.5 microns, wears off quickly. |

| Base Metal | Solid, heavier metals like brass, copper, or nickel-silver. | Lighter, cheaper metals like zinc, pewter, or even plastic. |

| Feel & Weight | Has a satisfying heft and feels substantial. | Feels lightweight, cheap, and sometimes flimsy. |

| Durability | Withstands regular use and cleaning without wearing away. | Scratches easily and the base metal shows through quickly. |

| Markings | Often has hallmarks like "EPNS," "A1," or micron thickness. | Usually has no markings or stamps at all. |

Ultimately, paying attention to these small details can make a huge difference in the longevity and appearance of your silver-plated items.

Decode the Hallmarks and Stamps

Especially on vintage and antique pieces, you’ll often find tiny stamps known as hallmarks. These little symbols are a roadmap to the item's history, telling you who made it and what it’s made of.

Here are a few common ones to look out for:

- EPNS: This is a classic mark you'll see a lot. It stands for Electro Plated Nickel Silver, meaning the base is a durable nickel-silver alloy.

- EPBM: This one means Electro Plated Britannia Metal, another popular and sturdy base material.

- A1 or Quadruple Plate: These are older marks that were used to signify a higher grade of plating. "Quadruple Plate" meant it had four times the standard amount of silver, while "A1" was often used to indicate a manufacturer's top-tier quality.

Once you know what to look for, you can start identifying high-quality silver plating with confidence, ensuring you choose pieces that will bring you joy for years to come.

Silver Plated vs. Sterling Silver: Key Differences

When you’re shopping for jewelry, understanding the difference between silver plated and sterling silver is one of the biggest hurdles. It's a common point of confusion, but there’s a simple way to think about it.

Imagine you're buying a table. A sterling silver piece is like a solid oak table—it’s made of the same high-quality material all the way through. A silver-plated item, on the other hand, is like a beautiful wood veneer table. It looks great on the surface, but underneath that thin top layer is a different, less expensive material.

Both can be beautiful and serve their purpose, but their construction, durability, and price are world's apart. One is a solid metal alloy, and the other is a layered creation. This single fact changes everything, from how the piece feels in your hand to how it will look in twenty years.

Composition: A Tale of Two Metals

The biggest difference comes down to what the item is actually made of.

- Sterling Silver: This is a precious metal alloy. For a piece to be legally called "sterling," it has to be at least 92.5% pure silver. The other 7.5% is typically copper, which is added to give the soft silver some much-needed strength. It’s silver from the surface to the core.

- Silver Plated: These items start with a base metal—often something like brass, copper, or nickel—and are then coated with a razor-thin layer of pure silver. The silver is only on the outside.

So, if you were to deeply scratch a sterling silver ring, you’d just see more sterling silver. But if you scratch a plated piece, you'll expose the different-colored base metal hiding underneath.

If you want to dive deeper into this, check out our guide comparing silver vs silver plated jewelry.

Durability and Longevity

Because it’s a solid alloy, sterling silver is built to last. It’s incredibly durable. Yes, it can tarnish over time, but that’s just a surface reaction that can be polished away, revealing the pristine metal underneath. A well-cared-for sterling silver piece can literally last for generations.

Silver plating, however, has a limited lifespan. That thin silver layer eventually wears away from friction, polishing, and exposure to your skin's oils. Once the plating is gone, the base metal shows through, and there's no going back.

The Cost and Weight Factor

For most people, the price tag is the most obvious difference. Sterling silver contains a large amount of a precious metal, which naturally makes it much more expensive than a plated item. The price of a sterling piece is directly linked to how much silver is in it.

A Matter of Value: The global silver market, valued at over USD 21.21 billion, shows just how high the demand is for this metal—not just in jewelry, but in things like solar panels and electronics. This intrinsic value is why solid sterling costs what it does. You can find more insights on the global silver market on marketdataforecast.com.

Weight is another dead giveaway. Sterling silver is a dense metal, so it feels heavier and more substantial in your hand. A plated piece of the same size will almost always feel lighter because the base metal isn't as dense. That heft is something many people associate with quality.

In the end, neither option is "better" than the other. They just serve different needs and fit different budgets.

The Surprising Uses of Silver Plating in Technology

When you think of silver plating, images of elegant cutlery or sparkling jewelry probably come to mind. But some of its most important jobs are hidden deep inside the technology we use every single day. Far from the dinner table, silver plating is a high-performance industrial workhorse, valued less for its looks and more for its incredible physical properties.

Silver's amazing electrical conductivity and natural resistance to corrosion make it an unsung hero in countless high-tech fields. It’s a key ingredient ensuring our modern world runs smoothly, from the smartphone in your pocket to the satellites orbiting our planet.

Powering Modern Electronics

In electronics, every connection matters. Silver is the most conductive of all metals, which means it lets electricity flow with almost no resistance. This efficiency is exactly why you'll find it coating all sorts of connectors, switches, and circuit board components.

That thin, precise layer of silver guarantees that critical electrical signals get where they need to go without being lost or interrupted. It's an absolute must-have for the reliable, high-speed performance we expect from consumer gadgets and complex aerospace systems alike.

Precious metal plating is a huge part of this industry, focusing on coating less expensive base metals to improve how they function and how long they last. The global market for this process, currently valued at around USD 240.90 million, is set to grow as our tech gets even more advanced. Silver is a major player here, hitting that sweet spot between cost and performance for electronics, automotive, and medical devices. You can read more about the growth of the precious metal plating market on straitsresearch.com.

Innovations in Energy and Medicine

Silver plating’s impact doesn't stop with electronics. It’s also playing a key role in renewable energy and healthcare, where its unique properties are helping build a more sustainable future and create safer medical environments.

Just look at a few of its game-changing applications:

- Renewable Energy: Solar panels use a silver coating to maximize how much electricity is captured and transferred from the photovoltaic cells, which directly boosts their efficiency.

- Automotive Industry: You'll find it coating engine bearings. Here, its low-friction surface helps reduce wear and tear, leading to better engine performance and a longer lifespan.

- Medical Devices: Silver is naturally antimicrobial, which is just a scientific way of saying it stops bacteria from growing. This makes it invaluable for plating surgical tools and medical implants, where it helps lower the risk of infection.

From safeguarding our health to powering our homes, silver plating proves its true value lies not just in its shine, but in its incredible scientific utility. It's a cornerstone of technological innovation, hidden in plain sight.

Simple Care Tips for Silver Plated Items

Proper care is the secret to making your silver-plated items last. Because that silver layer is so thin, harsh chemicals and aggressive scrubbing can wear it right off, revealing the base metal underneath. The golden rule is simple: always be gentle.

Think of it like a delicate coat of paint on a classic car. You wouldn't take a scouring pad to it, right? The same idea applies here. A light touch and consistent care will keep it shining and prevent the silver from wearing through prematurely.

Best Practices for Cleaning and Polishing

When your plated pieces start to look a little dull, it’s tempting to grab the first silver polish you see. That can be a huge mistake. Many commercial polishes are made for solid sterling silver and contain harsh abrasives that can strip the thin plating clean off.

Instead, stick to these simple steps for safe cleaning and polishing:

- Start with Mild Soap: A few drops of mild, phosphate-free dish soap in warm water is all you need. Gently wash the item with a soft sponge or cloth to get rid of any surface dirt and oils.

- Use a Non-Abrasive Cloth: For polishing, always reach for a soft, non-abrasive material like a microfiber cloth or a dedicated jeweler's cloth. This is the key to avoiding scratches that can permanently mar the finish.

- Polish Gently: Dab a tiny amount of polish made specifically for silver plate onto your cloth. Rub in gentle, circular motions, and don't apply too much pressure.

- Rinse and Dry Thoroughly: After cleaning, rinse the item completely with clean water. Then, immediately dry it with a soft, lint-free cloth. Water spots left behind can actually speed up tarnishing.

The most common mistake people make is over-polishing. Remember, every time you polish a plated item, you are removing a microscopic amount of silver. Less is always more.

Proper Storage Is Key to Longevity

How you store your silver-plated items is just as important as how you clean them. Tarnish is caused primarily by exposure to air and humidity.

To keep your pieces looking brilliant, store them in anti-tarnish bags or wrap each one individually in acid-free tissue paper. This creates a protective barrier that dramatically slows down the tarnishing process. For more in-depth instructions, you can learn how to clean silver jewelry at home in our comprehensive guide.

If the plating on a cherished piece does eventually wear off, don't despair—replating is an option. A professional jeweler can apply a fresh layer of silver, restoring its original beauty and giving it a whole new lease on life.

Common Questions About Silver Plating

Even after getting the hang of what "silver plated" means, some practical questions always seem to pop up. Let's tackle these common curiosities so you know exactly what to expect from your pieces and how to best care for them.

It's completely normal to wonder how your favorite plated jewelry will hold up over time or how it might react with your skin. Let's clear the air on some of the most frequent questions.

Does Silver Plated Jewelry Turn Your Skin Green?

This is a big one, and the short answer is: sometimes. But it's not the silver's fault. That harmless (but annoying) green tint happens when the thin silver coating wears down, exposing the base metal underneath. This is usually copper or a copper alloy like brass.

When the copper comes into contact with the sweat and natural oils on your skin, it oxidizes, leaving that familiar green mark behind. The good news is that higher-quality pieces with a thicker silver layer are far less likely to do this because the barrier is much stronger.

How Long Does Silver Plating Last?

Honestly, it all comes down to three key things: how thick the plating is, how often you wear or use the item, and how well you take care of it.

Think of it this way: a "flash plated" ring you wear every single day might start showing the base metal in under a year. On the flip side, a beautifully plated serving tray that's used only for special occasions and cleaned carefully could look perfect for 20 or 30 years. Proper care is everything.

The Bottom Line: Durability is a direct result of plating thickness and how much wear and tear an item gets. For anything you plan on wearing daily, a thicker plate is a much smarter investment.

Can You Get Silver Plated Items Wet?

You really want to avoid it. While a quick splash of water followed by a thorough drying probably won't hurt, moisture is the arch-nemesis of silver plating.

Here's what you should definitely skip:

- Showering or bathing with your jewelry on.

- Swimming, especially in chlorinated pools or salty ocean water.

- Washing dishes while wearing plated rings and bracelets.

Water has a sneaky way of getting into tiny, invisible cracks in the plating, which lets it start corroding the base metal from the inside out. This dramatically speeds up tarnish and damage. To get the full story, you can learn more about if silver plated jewelry will tarnish in our detailed guide.

At Hidden Forever, we believe your memories deserve to be preserved in materials that last. That’s why our personalized photo projection jewelry is crafted from genuine 925 sterling silver and 18k gold plating, ensuring your cherished moments shine brilliantly for years to come.

Explore our collection of timeless keepsakes at Hidden Forever.